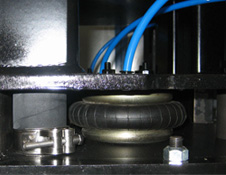

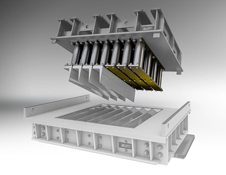

You would like to achieve greater productivity with your mould: less waste, wear, weight and noise as well as a longer life cycles and flexible settings on your machines. We can develop solutions for your specific needs based on your technical challenges.

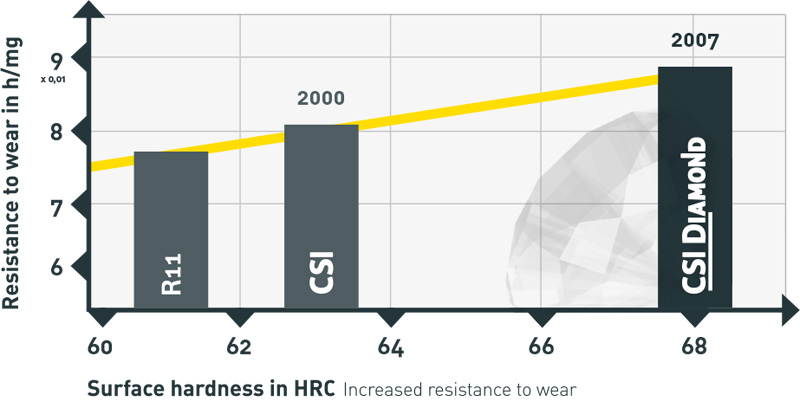

The pioneering spirit at RAMPF leads to a steady stream of new innovations in mould technology. We invented the CSI, CSI Diamond and CSI Nitro heat treating technologies. Optional extras, such as heated tamper shoes, centring of the tamper heads, density control, FlexWay® – or our brandnew NanoTech-Line – are milestones in mould manufacturing – and just a few examples of the tremendous technological innovation at RAMPF.